The ATLAS detector uses a number of different detectors: The inner detector provides the initial information from the proton-proton collisions at the Large Hadron Collider (LHC). It measures the direction, charge and momentum of the newly-created charged particles. The calorimeter provides information on the energy of the particles, and the muon spectrometer on their decays into muons. The evaluation of the muon tracks contributed to discover Higgs boson and to determine its exact mass.

New drift tubes improve the response behavior for muons

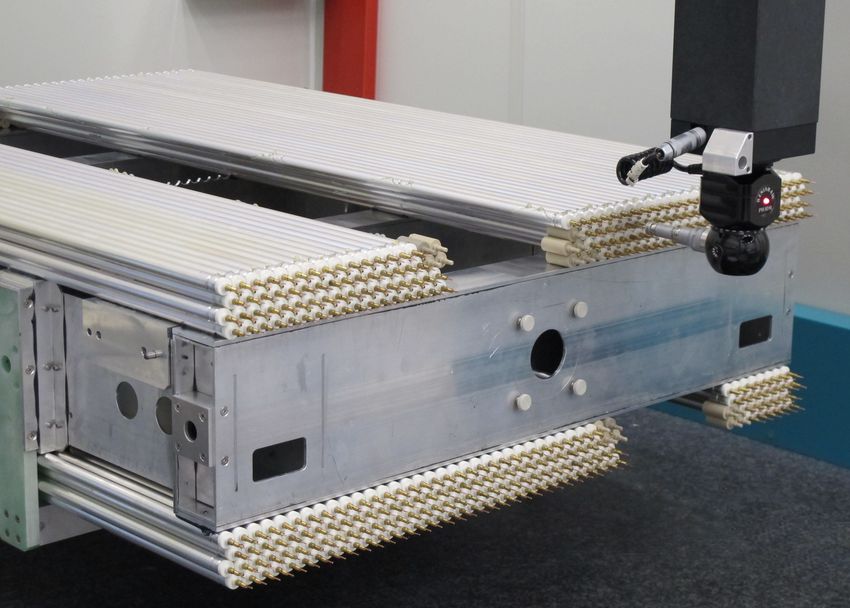

The ATLAS muon system uses a number of different instrument designs. The Max Planck Institute for Physics is developing and constructing the drift tube chambers, which are arranged around the center of the ATLAS detector. The new chambers have several advantages.

“The new drift tubes have a diameter of 1.5 centimeters, only half that of the earlier models. The signals can now be read out within 200 nanoseconds, namely four times faster than before. This means the drift tubes and their electronics are exposed less time to the neutron and gamma radiation omnipresent in the ATLAS detector – and are therefore able to respond again to muons 10 times faster,” explains Hubert Kroha, who heads the project group at the MPP.

These advantages are particularly important, as the Large Hadron Collider (LHC) has been running with the full collision energy of 13 teraelectronvolts and nearly twice the originally planned collision rate since 2015. “The proton collision rate will undergo a further fivefold increase during the next decade,” says Kroha. “This also makes it more of a challenge to separate muon data from unwanted background hits – a task which the new drift tubes are able to master very well.”

High precision and measurement accuracy

A higher response probability also improves the spatial resolution of the drift tubes, which will be 100 micrometers in the future. The spatial resolution of the muon chambers is crucial for the measurement accuracy of the muon pulses. These provide information on the mass of the Higgs boson or other, new particles.

A significant contribution to the high spatial resolution is provided by the incredible mechanical precision of the muon chambers. During construction of the chambers, the positions of the counting wires in the center of the drift tubes are mounted with an accuracy of 5 micrometers. In comparison: A human hair is around 100 micrometers thick.

Equipped for new generations of accelerators

The installation of the 12 new muon drift tube chambers is only the beginning of further modernization steps: In 2019, the inner layer of muon chambers in ATLAS will be supplemented by a further 16 modules. A massive upgrade of the muon spectrometer is planned from 2024 onwards. By 2026, the LHC will have been upgraded for even higher collision rates. In the "High Luminosity (HL)-LHC”, protons will then collide with each other ten times as frequently as they do today.

“This is where the properties of the improved muon chambers will really come into their own – and in a project that is still a long way away: There are already plans for the successor to the present LHC - the 'Future Circular Collider' at CERN is to have a circumference of 100 kilometers and almost ten times the collision energy,” says Kroha in conclusion.

Contact:

Dr. Hubert Kroha

Max Planck Institute for Physics

+49 89 32354-435